An Ingenious Device: The Pinch Polarizer Is Used All Over Space

By Albert McKeon

Sometimes, it takes a village to solve an aerospace engineering problem. Every once in a while, it also takes a village to realize the answer to the problem is an aluminum doughnut and not a plastic one.

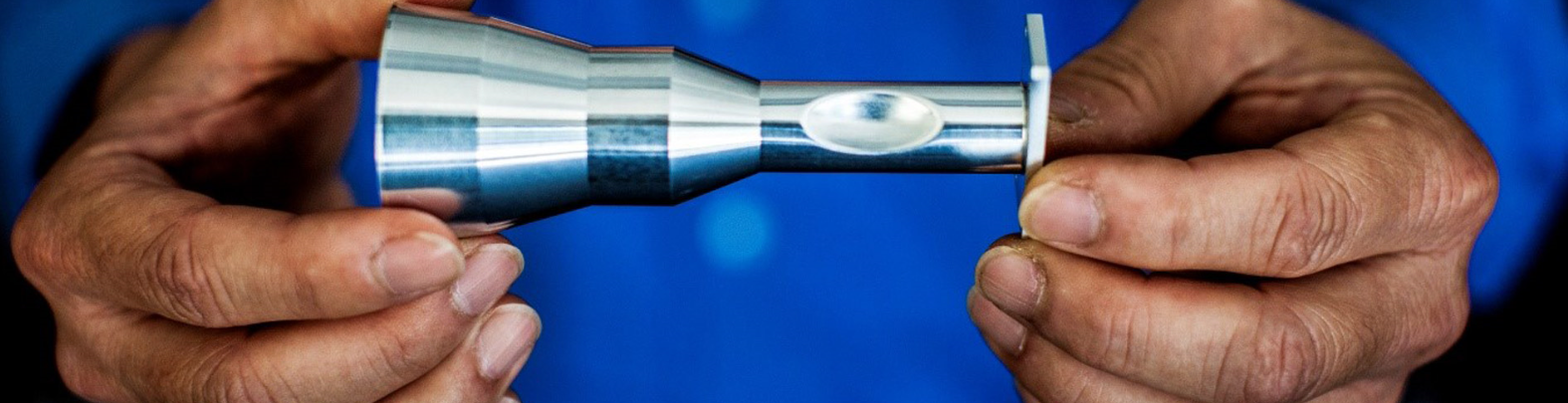

In the past decade, many of the thousands of satellites orbiting Earth have included that metal doughnut, which looks like a miniature trophy cup with a top cap when held upright. This ingenious device, known as the pinch polarizer, is a big deal in the space industry because, for relatively little cost and little production effort, it plays a big role in ensuring the transmission of satellite radio signals.

Steven Kuo, a Northrop Grumman engineer, invented the pinch polarizer. He came up with its unique design after seeing a faux doughnut on top of a pastry shop. He realized that integrating the circular shape of a doughnut at the opposite side of a device tapered on the other end would create the "pinch" needed to convert a linear radio signal into a circular one.

Engineering Collaboration Changes Satellite Radio Signal from Linear to Circular

Although invisible, a rounder radio signal has profound implications for satellite transmissions. Rather than being confined to a singular plane in a linear configuration, a circular signal can pass back and forth between the satellite and source on Earth without the need for either to reorient position. For instance, as long as a ship has its antenna pointed in the right direction, it doesn't need to stop or change direction to receive a signal while moving on an ocean, and as the satellite moves through space.

Behind the scenes, Kuo's collaboration with Northrop Grumman colleagues also lowered the production cost and increased the number of devices manufactured without sacrificing quality.

That collaborative spirit led them to overcome a seemingly insurmountable hurdle that threatened to derail the project.

Engineering and Manufacturing Teams Working Together

Getting the Right Team Together

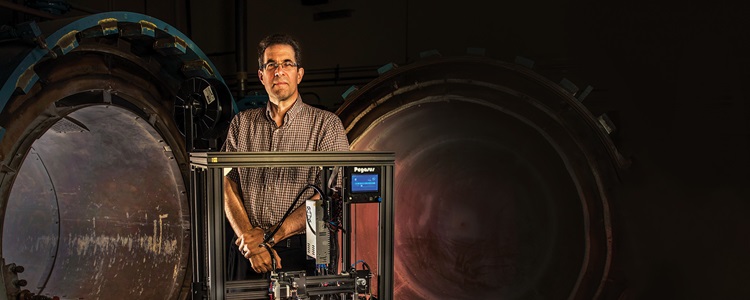

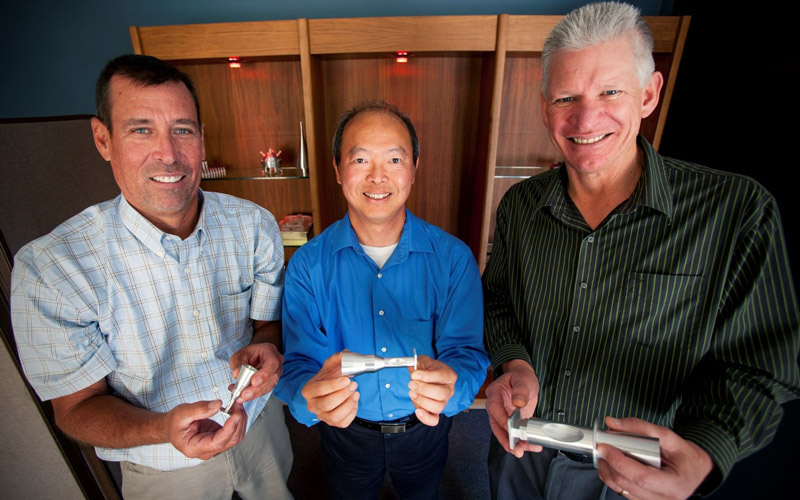

Kuo’s doughnut inspiration in 2000 became a reality with the help of several manufacturing engineers who worked in a test facility. He approached manufacturing supervisor Andy Roberts, manufacturing engineer Jim Ingram and their colleagues, asking for their support and input to create a lightweight device that wouldn't compromise the satellite signal integrity.

"You need everything to weigh as little as possible,” Kuo said. “Our original device was plastic, but the disadvantage was you would have to build it thick enough to be strong, so that meant you had to include metal surfacing. But with a metal joint, with some radio frequencies, you would have a drop-off in signal."

Years later, Ingram credits Kuo with having the humility to listen to suggestions that brought his creation to life. Instead of holding tightly to his design, Kuo "from day one, picked our brains and had a back-and-forth with us that came up with a design that was very producible."

Due to potential decreased transmission with plastic, the Northrop Grumman engineers went back to the drawing board. Whereas it took about three years to create and test the first iteration, the team now had a few months to re-do it because program funding would soon end, and reconsidered using aluminum.

"People said aluminum would be heavier and more costly," Kuo said. But he commends Ingram and his colleagues for making the most of the manufacturing machines to create an aluminum device strong enough and somehow lighter than the plastic one. It also outshone electrical performance and cost. The aluminum pinch polarizer has a 96% yield: only four out of every 100 are rejected in manufacturing.

Ingram recalls a key moment in that second go-around: "Imants Eglitis, a manufacturing engineer, said, 'Let's make it a three-piece device that allows it to collapse.'" This big tweak allowed the pinch polarizer to maintain its fidelity and thus preserve the satellite signal strength.

"When I started, I was mainly a machinist. You were given a design and you just made it…no one really questioned the design," said Ingram, who retired from Northrop Grumman after 34 years but has since returned as a part-time contractor. "The idea we strive for now is to get the right people together from day one."

Kuo couldn't have imagined a better outcome for his doughnut idea. "That's how things work here," he said. "You have to interact with the different disciplines. Nobody can know everything. You have to communicate and talk."

He'll never forget his joy when he heard the satellite that contained the first pinch polarizer leave Earth. He was driving on vacation and called in to listen to the launch. "That's the kind of ownership you really want to see. To know your product got to space." Since then, several thousand versions of his ingenious device have facilitated satellite transmissions.

More Innovation Stories

Read all stories about advanced technology and innovation >>