Photo Credit: NASA

Artemis

Building on our mission heritage to enable NASA to return humans to the moon and beyond.

From the first lunar lander and the space shuttle boosters, to supplying the International Space Station with vital cargo, Northrop Grumman has pioneered new products and ideas that have been put into orbit, on the Moon, and in deep space for more than 50 years.

As a part of NASA’s Artemis program, we are building on our mission heritage with new innovations to enable NASA to return humans to the moon, with the ultimate goal of human exploration of Mars.

What is Artemis?

NASA’s Artemis program will land the first woman and next man on the Moon, using innovative technologies to explore more of the lunar surface than ever before and establish sustainable exploration by the end of the decade. NASA will then use this knowledge to take the next giant leap – sending astronauts to Mars.

Supporting NASA's Artemis Program

Northrop Grumman supports NASA's Artemis program by providing the solid rocket boosters for the NASA Space Launch System and the abort motor and attitude control motor for the Orion spacecraft’s Launch Abort System. Additional information about these motors can be seen below, with detailed information available in the SLS Motors section of Northrop Grumman’s Propulsion Products Catalog.

We’re also building the Habitat and Logistics Outpost (HALO) module for NASA’s lunar gateway. Building on our demonstrated success with our Cygnus spacecraft, we are designing and constructing HALO to provide a safe and versatile habitation element for the Lunar Gateway. We are also bringing our spaceflight experience in power systems, other vehicle systems, and mission planning and training to the Intuitive Machines team to build the Lunar Terrain Vehicle (LTV).

Space Launch System Boosters

Northrop Grumman manufactures the five-segment solid rocket boosters for the NASA Space Launch System (SLS). These are the largest human-rated solid rocket boosters ever built for flight.

Each motor consists of five rocket motor segments, thrust vector control and an aft exit cone assembly; it is 153 feet long and 12 feet in diameter. The entire booster (including nose cap, frustum, and forward and aft skirts) are approximately 177 feet long. Of the booster's total weight of 1.6 million pounds, propellant accounts for 1.5 million pounds.

Northrop Grumman conducts full-scale static tests of its motors to qualify upgrades and to ensure flawless operation. A number of quality inspections are also performed throughout the booster's manufacture, including X-ray, ensuring it will perform exactly as predicted.

The SLS provides a new capability for human exploration beyond Earth orbit. Designed to be flexible for crew or cargo missions, the SLS is safe, affordable and sustainable, to continue America's journey of discovery from the unique vantage point of space. The SLS will take astronauts farther into space than ever before, while engaging the U.S. aerospace workforce here at home.

Booster Separation Motor

Northrop Grumman's Booster Separation Motors (BSMs) were rigorously qualified for manned space flight, successfully used on the last 15 space shuttle missions, and are a critical part of NASA's next-generation Space Launch System (SLS). Four BSMs are installed in the forward frustum of each solid rocket booster, and four are installed in the aft skirt.

Designed to push the spent motors safely away from the core vehicle at staging, all 16 BSMs fire simultaneously at booster separation a little over two minutes into the mission, approximately 25 nautical miles above the earth's surface. Travelling 3,000 miles per hour at ignition, each BSM provides about 20,000 pounds average thrust over its one-second burn, ensuring successful launch to orbit.

Orion Spacecraft Launch Abort Motor

Northrop Grumman manufactures the main abort motor and attitude control motor that are an integral part of the Launch Abort System for NASA's Orion spacecraft that will launch atop NASA's Space Launch System and carry crew to deep space missions. The Space Launch System incorporates the Launch Abort System to safely lift the Orion crew module away from the launch vehicle in the event of an emergency on the launch pad or during ascent.

Northrop Grumman, along with NASA and Lockheed Martin, successfully completed qualification of the abort motor with three ground test firings of the abort motor at the company's Promontory, Utah, facility.

The abort motor can exert 400,000 pounds of thrust in one-eighth of a second for approximately five seconds and features a revolutionary turn-flow rocket manifold technology that balances thrust and maximizes performance all at a safe distance from the crew capsule. The abort motor also incorporates a lightning strike protection system to improve crew safety.

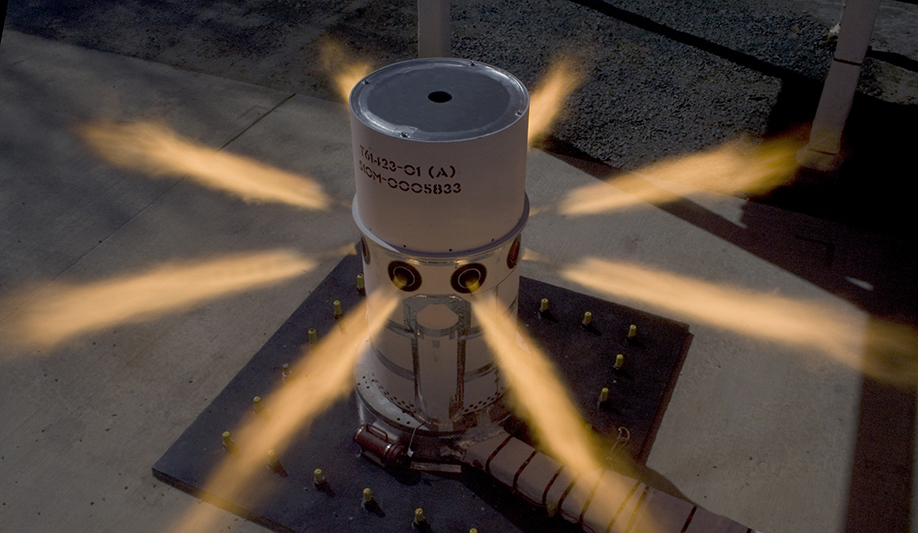

Orion Spacecraft Attitude Control Motor

Northrop Grumman's attitude control motor (ACM) consists of a solid propellant gas generator with eight proportional valves equally spaced around the circumference of the motor. All together, the valves exert up to 7,000 lbs of steering force to the vehicle in any direction.

The ACM's valve control is fully redundant. The motor has two critical functions: steer Orion's launch abort system and crew module away from the launch vehicle in the event of an emergency and orient the capsule for parachute deployment once cleared from hazard.

The first active Launch Abort System will be integrated into the Orion spacecraft for Artemis II, the first crewed launch, and increase astronaut safety as we humans to explore the moon, Mars and other deep space destinations beyond low-Earth orbit.

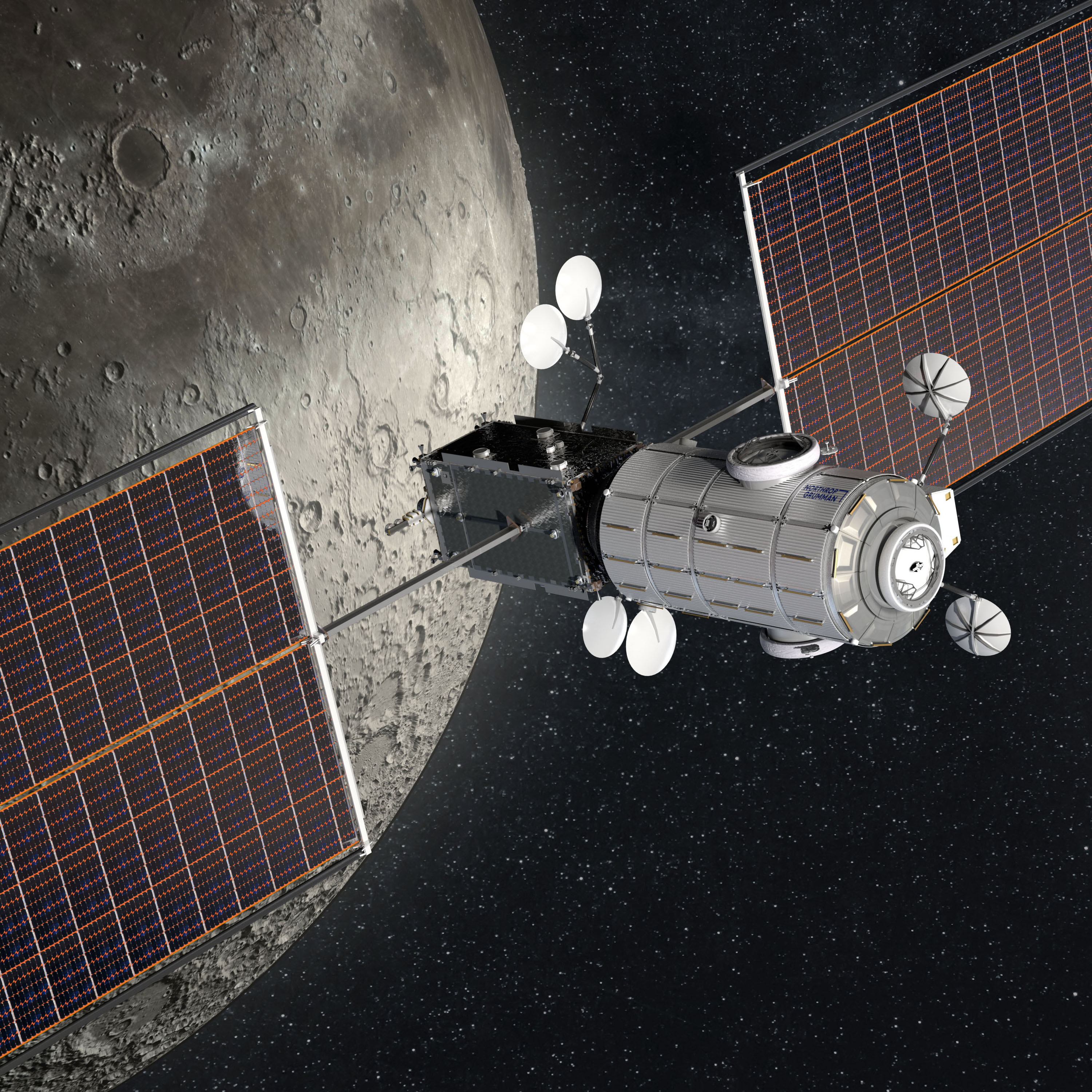

Habitat and Logistics Outpost (HALO)

NASA awarded Northrop Grumman a sole source contract to build the Habitat and Logistics Outpost, or HALO, for cislunar orbit. HALO will utilize environmental controls and life support systems to house astronauts during lunar missions. The module will be able to support a crew of four astronauts for up to 30 days and will have command, control and data capabilities, energy storage and power distribution, thermal control, and communications and tracing capabilities. HALO will also feature up to four docking ports for visiting spacecraft, including NASA’s Orion spacecraft and other logistics support vehicles. HALO will enable sustainable and flexible exploration of the Moon and is necessary for future deep exploration mission and the journey to Mars.

Designs for HALO are based on Northrop Grumman’s highly successful Cygnus spacecraft, a human-rated vehicle that is used to carry crew supplies, equipment and scientific experiments to the International Space Station.

Artemis in the News