Virtual Reality Brings Engineers to the Moon

By Kelly McSweeney

How do you go to the moon without actually going to the moon? Virtual reality (VR). This brings space closer to home so that engineers can see their designs in action. On the NextSTEP-2 program, the precursor to HALO, the Northrop Grumman team used VR and 3D printing to create models of habitat modules for the Gateway, NASA's outpost that will orbit the moon.

VR for Evaluating and Improving Designs

At Northrop Grumman's VR lab in Dulles, Virginia, engineers used virtual reality to evaluate and improve their designs before getting hands-on with 3D-printed mock-ups of key module features. By slipping on a headset, they were able to step into the crew's shoes and test the feasibility of procedures, such as operating a robotic arm or cleaning the module in a zero-gravity environment.

Computer-aided design (CAD) helped to advance engineering from paper to computer. And while CAD designs are widely used today, they are still limited by the screen. For projects such as satellites and habitats for space, prototypes are crucial for helping engineers evaluate and improve their designs. However, it simply isn't feasible to test designs in the environment in which they will operate. Virtual reality helps to bridge that gap so that engineers can mimic scenarios to see if there is anything in the design that should be tweaked.

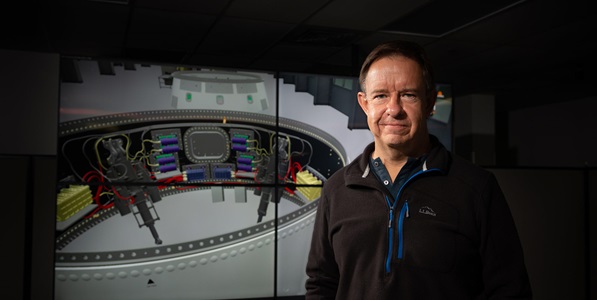

"Before building an expensive prototype, we can take the models that are being designed and we can look at them through VR to help make sure we are making the right decisions, especially since human factors play a large role," Lead Systems Engineer Adeena Mignogna explains.

At the VR Lab, software engineers convert CAD models into a format that gaming systems can read. They use a 3D creation tool called Unreal Engine.

"It has all the physics models and some of the math built in, so we don't have to program it from scratch," Mignogna says. "It has the baseline, and we program the specifics."

Simulations for Unearthly Situations

Next, they can prepare scenarios and place the converted model into the scene to see what happens. That way, they can uncover challenges that might occur in an enclosed environment in space. For example, a repair that would be simple on Earth becomes more complicated if your wrench floats away in space.

They created a fire scenario and simulated smoke to see how quickly astronauts could reach a fire extinguisher when their vision is impaired by smoke. But designing a habitat is more complicated than just building a perfect module — it also depends on the people who will be in it.

"During a high-radiation event, there is a procedure for how the crew can protect themselves," says Alishan Hassan, principal engineer at Northrop Grumman.

He explains that if astronauts need extra radiation protection, they can create a shelter by rearranging payload racks, which are storage drawers that normally hold tools and science experiments. In order to make sure that this emergency plan would actually work, they simulated the procedure with VR and then later tested it in the physical prototype.

Working on the Cutting Edge – for Now

Mignogna suggests that, while virtual reality is cutting-edge now, it could become a standard step in the design process in the next decade or so.

"I'm hoping that we can make this be normal," she says. "I've heard stories from my elders about how we did engineering before email. I think I will be telling the next generation what it was like before VR."

More innovation stories

Read all stories about advanced technology and innovation >>