In a League of Its Own

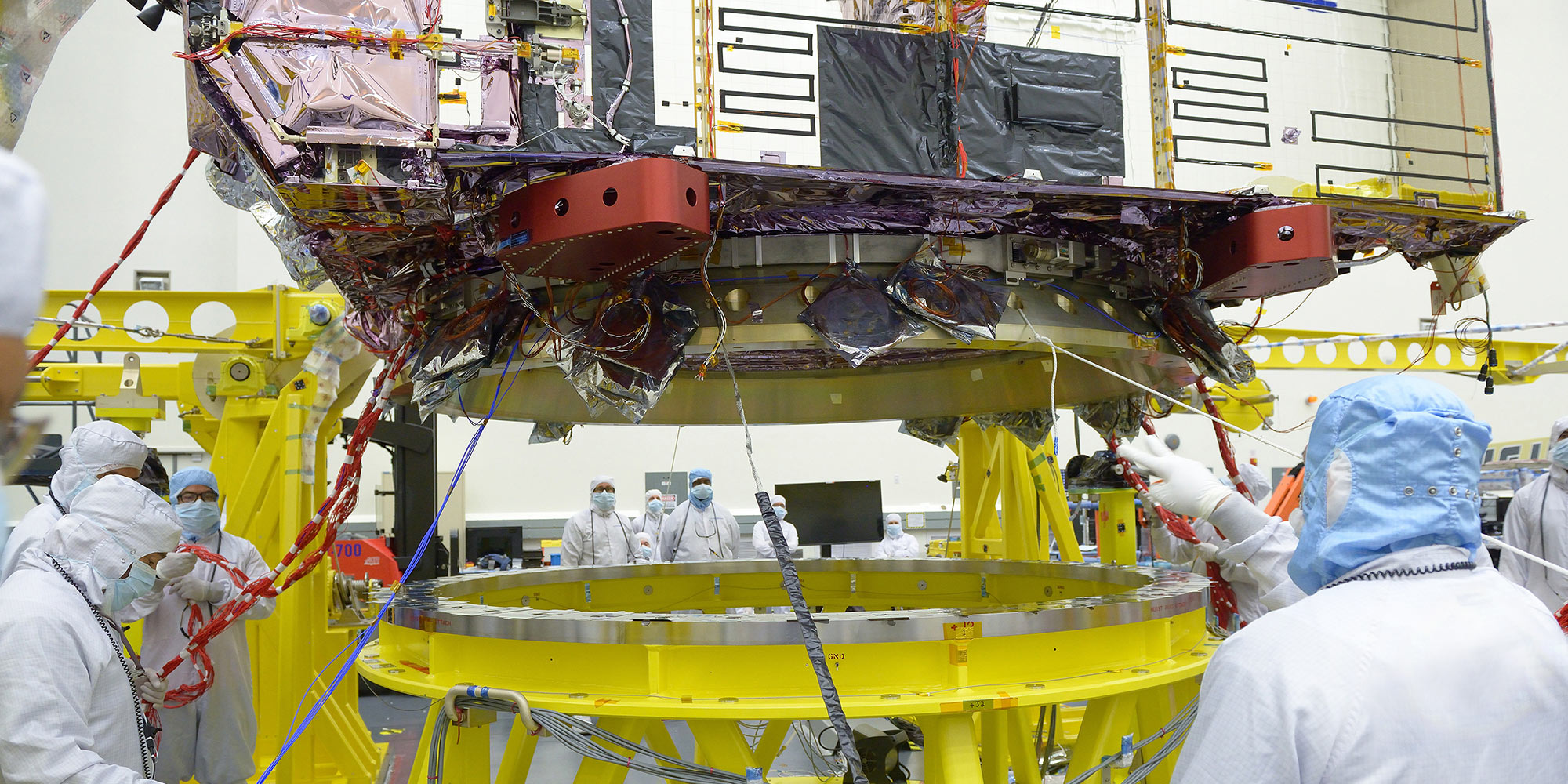

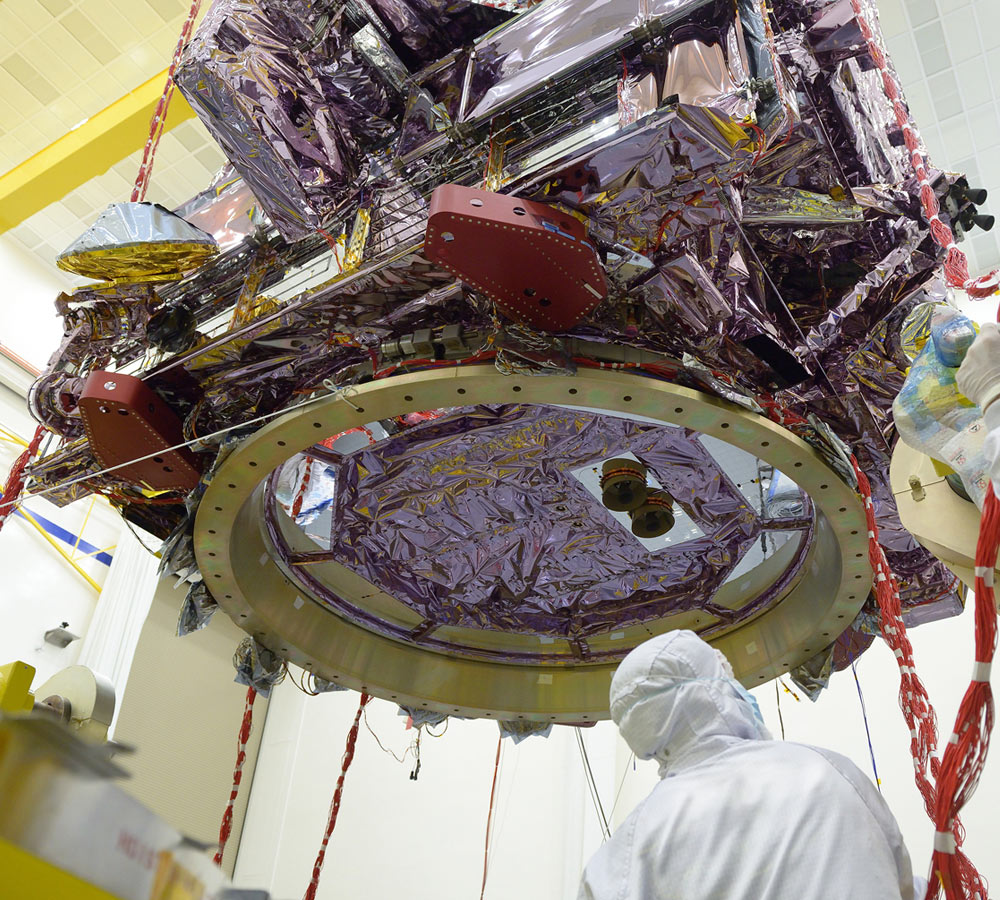

The Spacecraft Bus for the James Webb Space Telescope

By Scott Gourley

Often, one of the most critical elements in a space launch is the easiest to take for granted.

While the payload itself typically garners the most attention, it's the spacecraft bus that carries and supports every aspect of the mission for the life of that craft. And in the case of the James Webb Space Telescope, the bus performs its vital role with a robust and trusted design that sets a new standard for engineering creativity. The bus is really the ‘infrastructure’ of the observatory and consists of the ‘guts’ of the whole space-flying machine - the power, communications, attitude control and thermal control subsystems, and on-board computing power that are necessary to ‘fly’ the observatory.

Supporting a New Generation in Space Exploration

Following its planned launch from French Guiana later this year, Webb will provide an orbiting infrared observatory using the world’s most advanced space telescope and science instruments.

"The telescope is the reason we have this mission, so it tends to be center stage," observed Micah Abelson, Northrop Grumman Mechanical Design Manager. "And the other really impressive part is the sunshield that is deployed with the telescope. But it's the spacecraft bus beneath them that makes it all happen." Drawing on a company history of developing reliable spacecraft buses for heavy-duty space missions, Northrop Grumman engineers began designing Webb’s bus in 2007 and delivered it for integration in 2016.

Spacecraft Bus Design Challenges

"The spacecraft bus was the last major element of the program to start," Abelson explained. "You might say that boxed us into an engineering corner. Everything had to be strong enough and stiff enough to support the payload, but we were given a finite mass to work within. It was very challenging."

He also pointed out that mass is always a driving design factor when it comes to spacecraft. In fact, his team devoted nearly two years of study and redesign just to try and minimize mass.

Some of that redesign involved the creation of new structures with greater efficiency, while other options explored the use of different materials. Admitting that some of the new materials might have been a little harder to work with, Abelson quickly asserted that the positive trade-off was greater strength and a corresponding reduction in the amount used.

"It's easy to design something if you can throw steel at it," he said. "But the problem is, you end up with something that can't get off the planet."

Those challenges led the design team to explore a number of innovative solutions.

One example Abelson cited involves the cryogenic cooler, which cools one of the telescope’s Science Instruments to a few degrees from absolute zero. To eliminate any vibration while still removing generated heat, they used heat pipes to serve as structural support while also isolating cooler vibrations.

The team applied unique design thinking to Webb’s three star trackers that analyze star fields to determine the exact orientation of the telescope.

"There are things on the bus that vibrate," Abelson noted. "And there are isolators between the bus and the telescope. But we also had very stringent stability requirements for the star trackers."

He described the final star tracker design as a long, thin structure floating in the middle of the bus and connected directly to the telescope.

"That was probably the single most challenging thing we have on the bus — getting that designed and making that whole system work properly," he said.

Lessons Learned for Future Spacecraft

Asked whether any aspects of Webb’s bus design process might be applicable to future spacecraft payloads, Abelson replied that some of the approaches would likely remain unique to this particular spacecraft bus mission.

"Some of the concepts, like using heat pipes as an isolator, worked for us," he said. "But it's also a little unusual. You typically would want something more structural to support things.” Abelson continued, “On all the work we do on an exquisite program like Webb, we take the learnings and innovation and apply those concepts to smaller, faster satellite and spacecraft projects.”